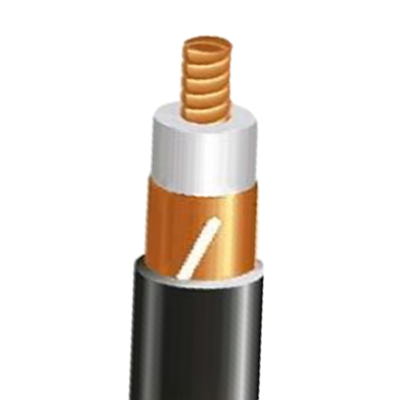

Description

| Weight (+5%) |

F-R Jacket |

Nominal 0.92 kg/m |

| Single Bending Radius |

|

400 mm |

| Multiple Bending Radius |

|

500 mm |

| Bending Moment |

|

14.0 N-m |

| Minimum Distance to Wall |

|

80 mm |

| Recommended Hanger Spacing |

|

1.0 m |

| Tensile Strength |

|

2000N |

| Environmental Specification |

|

|

| Operating Temperature |

F-R Jacket |

-40℃~+70℃ |

| Installation Temperature |

|

-20℃~+60℃ |

| Storage Temperature |

|

-40℃~+70℃ |

| RoHS |

|

Compliant |

| Standard Condition |

|

|

| Attenuation Test Method |

|

IEC 61196-4 |

| Attenuation Ambient Temperature |

|

20℃ |

| Average Power, Ambient Temperature |

|

40℃ |

| Average Power, inner Counductor Temperature |

|

100℃ |

| Coupling Loss Test Method |

|

IEC 61196-4 |

| Reference Standard |

|

|

| Flame retardant property |

|

IEC 60332-1-2,IEC 60754-1/-2 |

| DC Resistance Inner Conductor |

2.00 Ω/km |

| DC Resistance Outer Conductor |

3.00 Ω/km |

| Dielectric Strength |

DC 10,000V For 1 Min |

| Min. Insulation Resistance |

5,000 MΩ.km |

| Velocity of Propagation |

89+2% |

| Jacket Spark Test Voltage |

10000V |

| Characteristic Impedance |

50+2Ω |

| Capacitance |

76 pF/m |

| VSWR |

|

| 698~960 |

Max.1.30 |

| 1700~1900 |

Max.1.30 |

| 1920~2025 |

Max.1.40 |

| 2110~2170 |

Max.1.40 |

| 2300~2700 |

Max.1.40 |

| 3300~3700 |

Max.1.40 |

| Frequency (MHz) |

Attenuation dB/100m |

Coupling Loss 95% (2 MTR) |

| 700 |

2.7 |

85 |

| 800 |

2.8 |

78 |

| 900 |

2.0 |

76 |

| 1800 |

4.6 |

72 |

| 1900 |

4.8 |

71 |

| 2000 |

5.0 |

70 |

| 2400 |

5.8 |

69 |

| 2600 |

6.2 |

69 |

| 2700 |

6.5 |

68 |

| 3400 |

8.4 |

67 |

| 3500 |

9.0 |

67 |

| 3600 |

9.0 |

67 |

| 3700 |

11.2 |

68 |

| 3800 |

12.0 |

67 |

- *Attenuation / Coupling Loss are nominal values.

- *The attenuation may rise by 0.2%/℃ with ambient temperature rising.

- *Maximum attenuation value shall not exceed 105% of nominal value.

- *Maximum coupling loss value shall not exceed “nominal value ± 10dB”.

We are continuously working to enhance our products; therefore, specifications may change. For the latest details, please feel free to contact us.